The Dyson DC24 is a popular vacuum cleaner known for its ball technology and powerful suction. However, like any electronic device, it can experience issues that prevent it from turning on. If your Dyson DC24 refuses to power up, don’t worry – many common problems have straightforward solutions. This guide will walk you through the most frequent causes and how to address them, potentially saving you from an expensive repair or replacement.

Affiliate disclosure: As an Amazon associate, We'll earn a commission for every successful order through our affiliate links in the article. However, you won’t be charged anything for this.

Before rushing to a repair shop or considering a new purchase, it’s worth investigating the issue yourself. Many Dyson DC24 power problems can be resolved with basic troubleshooting and simple repairs. The following sections will help you identify what’s wrong with your vacuum and guide you through the necessary steps to get it working again.

Common Causes of Power Issues in Dyson DC24

When your Dyson DC24 fails to turn on, several potential culprits could be responsible. Understanding these common causes will help you diagnose the problem more efficiently.

Faulty On/Off Switch

One of the most common reasons a Dyson DC24 won’t turn on is a defective power switch. You might notice that the start button won’t stay down when pressed, or the motor briefly runs while holding the button but immediately stops when released. This behavior typically indicates that the switch mechanism has failed and needs replacement.

The switch (part number 6 in most models) is a high-wear component due to frequent use. Over time, the internal contacts can become worn or damaged, preventing proper electrical connection when activated.

If the power switch is indeed the problem, replacing it with a new one is the solution.

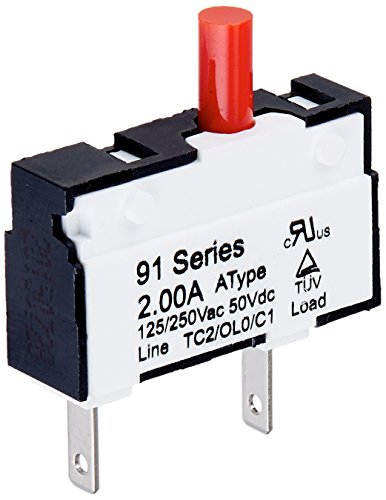

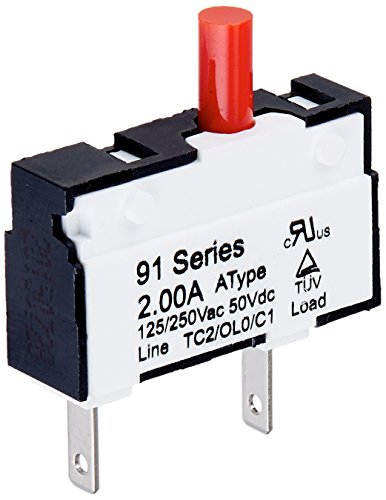

Genuine OEM part with thermal protection for DC24/25 models

OEM authorized thermal circuit breaker for DC24/25

Third-party switch with broad compatibility and warranty

Circuit Board Problems

The circuit board is essentially the brain of your Dyson DC24. When damaged, it can prevent power from reaching the motor or cause erratic behavior. Signs of circuit board issues include:

- Complete lack of power despite a working outlet and power cord

- Burning rubber smell during operation

- Visible electrical arcs when attempting to turn on the vacuum

- Intermittent operation

Circuit board problems often stem from blown resistors, damaged capacitors, or cold solder joints. These components can fail due to power surges, overheating, or simply age.

Jammed Brush Roller

While a jammed brush roller might not prevent the vacuum from turning on entirely, it can trigger safety mechanisms that shut down operation. The Dyson DC24 has a safety feature that disengages the brush bar when obstructions like shoelaces get tangled in it. When this happens, a red safety component may become dislodged, stopping the brush from spinning.

If your vacuum powers on but the brush doesn’t rotate, this could be your issue. The vacuum might also shut down completely if the system detects a serious jam that could damage the motor.

If the brush roller is damaged beyond repair, consider replacing it to restore your Dyson’s cleaning performance.

Affordable third-party replacement with included cleaning brush

Durable with adjustable rotation for hair prevention

30-day warranty and easy installation

Budget option with stiff bristles for effective cleaning

Overheating Motor

An overheating motor can trigger thermal protection features that prevent the vacuum from turning on. Signs of this issue include:

- The reset button repeatedly popping out

- Motor becoming extremely hot during operation

- Smoke or burning smell

- Vacuum shutting off unexpectedly during use

Overheating typically occurs due to clogged filters, blocked airways, or debris buildup around the motor. In some cases, the motor itself may be failing and require replacement.

If the motor is indeed failing, a replacement is necessary to get your Dyson running again.

Genuine Dyson main motor for DC24 model

OEM-authorized motor assembly for multiple Dyson models

Loose Wire Connections

Sometimes, the issue is as simple as a loose wire connection between components. Mechanical stress from regular use can cause wires to disconnect, particularly between the beater bar and main motor circuits. This problem is often overlooked but is relatively easy to fix once identified.

Diagnosing Your Dyson DC24 Power Problems

Before attempting any repairs, you need to accurately diagnose the issue with your vacuum. Here’s a systematic approach to troubleshooting your Dyson DC24.

Visual Inspection

Start with a thorough visual inspection of your vacuum:

- Check the power cord for any visible damage, cuts, or fraying

- Inspect the plug for bent prongs or burns

- Look at the on/off switch for signs of damage or wear

- Examine the vacuum for any obvious physical damage

This initial inspection can quickly reveal simple issues like a damaged power cord that’s preventing electricity from reaching your vacuum.

If the power cord is damaged, it’s crucial to replace it for safety and proper operation.

Official replacement for Dyson DC24 vacuum

36ft compatible cord with extended warranty

Testing the Power Supply

Before diving into complex repairs, confirm that power is reaching your vacuum:

- Try plugging the vacuum into different outlets to rule out a faulty wall socket

- Check if the circuit breaker for that outlet hasn’t tripped

- If you have a multimeter, test the outlet to confirm it’s providing the correct voltage

Checking the On/Off Switch

To test if the on/off switch is the culprit:

- Press the power button and listen for any clicking sounds

- Notice if the button feels different than normal (stuck, loose, or unresponsive)

- Check if the vacuum runs momentarily when holding the button but stops when released

Examining the Brush Roller

If the vacuum powers on but doesn’t clean effectively:

- Turn the vacuum over and check if the brush roller spins freely

- Look for any visible obstructions, hair, or string wrapped around the brush

- Check for the red safety component to see if it’s properly seated

Step-by-Step Repair Guide for Power Issues

Once you’ve identified the likely cause of your Dyson DC24’s power problems, follow these detailed repair procedures to get your vacuum working again.

Replacing a Faulty On/Off Switch

If you’ve determined that the power switch is defective, here’s how to replace it:

- Unplug the vacuum completely from the power source

- Locate the switch (part number 6 in most models)

- Remove the screws securing the switch to the base unit

- Carefully disconnect any wires connected to the old switch, noting their positions

- Connect the wires to the corresponding terminals on the new switch

- Install the new switch, ensuring it sits properly in its housing

- Secure the switch with the screws you removed earlier

- Test the vacuum to confirm the issue is resolved

Repairing Circuit Board Issues

Circuit board repairs require more technical skill but can often be accomplished with basic soldering equipment:

- Unplug the vacuum and ensure it’s completely powered down

- Access the circuit board by removing the necessary components

- Visually inspect the board for blown components, scorched areas, or loose connections

- Clean the board using a stiff toothbrush and isopropyl alcohol to remove any conductive residue

- Check for cold solder joints (dull, cracked connections) and resolder them

- Test components with a multimeter:

- Check resistors for continuity

- Test capacitors (especially the 100uF 400V capacitor)

- Verify diodes in the bridge rectifier (GBU807) for proper function

- Replace any faulty components with compatible parts

- Reassemble the vacuum and test its operation

Clearing a Jammed Brush Roller

To address brush roller issues:

- Unplug the vacuum for safety

- Turn the vacuum over to access the brush head

- Remove the brush head from the vacuum (consult your user manual for the specific procedure)

- Inspect the brush roller for debris, hair, or other obstructions

- Use scissors or a seam ripper to carefully cut away tangled materials

- Check for the red safety component and reinsert it into its designated slot if dislodged

- Ensure the brush rotates freely before reassembly

- Reattach the brush head and test the vacuum

Addressing an Overheating Motor

For motor overheating issues:

- Unplug the vacuum and allow it to cool completely

- Remove and clean all filters according to the manufacturer’s instructions

- Check for blockages in the suction pathway and clear them

- Clean the brush head thoroughly, removing any wrapped hair or debris

- Inspect the belt spindles to ensure they rotate freely

- If the motor continues to overheat after cleaning, it may need replacement:

- Advanced users can test the motor by connecting it to a 12V automotive battery

- If it doesn’t turn or runs erratically, the motor requires replacement

Fixing Loose Wire Connections

To address loose wire connections:

- Unplug the vacuum completely

- Check the 2-amp breaker near the beater bar switch

- Disassemble the vacuum housing by removing:

- The canister

- The hose

- The three T15 Torx screws securing the housing

- Carefully inspect all wire connections, looking for any that appear loose or disconnected

- Pay special attention to connections between the beater bar and main motor circuits

- Reattach any loose wires, ensuring they’re securely connected

- When reassembling, ensure proper alignment of all components

- Test the vacuum to confirm the repair was successful

Troubleshooting Specific Dyson DC24 Issues

Fixing a Wobbling Ball Assembly

The ball assembly is a distinctive feature of the Dyson DC24 that can develop problems over time:

- If your vacuum’s ball wobbles excessively, the white nylon bearing may be damaged

- To replace it:

- Recline the vacuum and remove the HEPA filter

- Using a T15 Torx screwdriver, remove the four screws securing the ball halves

- Extract the damaged bearing

- Slide the replacement bearing onto the shaft

- Reassemble the ball, ensuring proper alignment

- The ball should have minimal play for smooth rotation but shouldn’t be excessively tight

If the white nylon bearing is damaged and causing the wobble, replacing it is the solution.

Official OEM replacement for Dyson DC24 ball bearing

Affordable generic bearing assembly for DC24 brushroll

Addressing a Stuck Roller Brush Switch

If your roller brush continues to spin even when it should be off:

- Unplug the vacuum for safety

- Remove the canister to access the roller brush assembly

- Remove the screws securing the roller brush assembly using a T15 Torx screwdriver

- Access the switch mechanism

- Clean the switch and surrounding area with a damp cloth and mild detergent

- Apply a small amount of suitable lubricant if the switch feels stiff

- Test the switch to ensure it moves freely

- If the switch remains stuck, replace it with a new one

- Reassemble the vacuum and test its operation

If cleaning and lubricating the switch doesn’t resolve the issue, replacing it is the next step.

OEM reset switch for Dyson uprights, ensures proper brushroll function

Shut-off switch with overload protection for DC50 uprights

Reset switch for DC25/DC24 thermal overload protection

Resolving Beater Bar Switch Problems

The beater bar switch is a common failure point that can prevent proper operation:

- Unplug the vacuum and disassemble the housing as described earlier

- Locate the beater bar switch (a 2-amp circuit breaker)

- Use a multimeter to verify switch functionality

- To replace the switch:

- Carefully handle the spring clamps

- Note the wiring orientation (gray spring first, followed by red spring)

- Insert the new switch with precise alignment

- Ensure all connections are secure during reassembly

- Test the vacuum to confirm proper operation

If the beater bar switch is faulty, replacing it with a new one is necessary.

Genuine Dyson replacement for DC24 beater bar reset

OEM replacement with same part number for DC24

Third-party compatible with 200-day warranty

Frequently Asked Questions (FAQ)

Why does my Dyson DC24 turn on but shut off immediately?

This typically indicates either a faulty power switch or an overheating protection mechanism. If the vacuum is hot to the touch, allow it to cool completely before attempting to use it again. Clean all filters and check for blockages. If the problem persists, the power switch likely needs replacement, as the button may not be staying engaged when released.

What should I do if my Dyson DC24’s brush isn’t spinning?

First, check for obstructions like hair or string wrapped around the brush. If none are found, look for the red safety component that may have become dislodged. This safety mechanism disengages the brush bar when it encounters obstacles. Reinsert the red component into its designated slot to reactivate the brush bar’s rotation. If this doesn’t resolve the issue, the brush motor or belt may need replacement.

How can I tell if my Dyson DC24’s circuit board is damaged?

Signs of circuit board damage include burning smells during operation, visible electrical arcs when turning on the vacuum, or complete power failure despite a functioning outlet and power cord. You might also notice scorched areas on the board itself when opened for inspection. Testing components with a multimeter can confirm specific failures like blown resistors or faulty capacitors.

My Dyson DC24’s ball assembly wobbles excessively. Can I fix this?

Yes, excessive wobbling is typically caused by a damaged white nylon bearing. This can be replaced by reclining the vacuum, removing the HEPA filter, and accessing the four screws that secure the ball’s halves using a T15 Torx screwdriver. After replacing the bearing, ensure the ball has minimal play for smooth rotation while avoiding excessive tightness that could impede movement.

Why does my Dyson DC24 keep overheating?

Overheating usually occurs due to restricted airflow. Ensure all filters are clean, the dust canister is empty, and there are no blockages in the suction pathway. Check that the brush roller spins freely and isn’t jammed with debris. If overheating persists after thorough cleaning, the motor may be failing and require replacement, or there could be an electrical issue with the circuit board.

Conclusion

The Dyson DC24 is a well-designed vacuum with several common failure points that can prevent it from turning on. By following the diagnostic steps and repair procedures outlined in this guide, you can identify and fix many issues without professional assistance.

Remember that safety should always be your priority when working with electrical appliances. Always unplug your vacuum before attempting any repairs, and don’t hesitate to seek professional help if you’re uncomfortable performing these procedures yourself.

Regular maintenance can prevent many of these issues from occurring. Empty the canister after each use, clean filters regularly, and check the brush roller for tangled hair or debris. With proper care and occasional troubleshooting, your Dyson DC24 can provide many years of reliable service.