Your Dyson DC14 has stopped picking up debris from your carpet, leaving you frustrated and your floors dirty. This comprehensive guide will walk you through the most common causes and solutions for this problem, from simple maintenance tasks to more complex repairs. By following these troubleshooting steps, you’ll be able to restore your vacuum’s suction power and get your carpets clean again.

Affiliate disclosure: As an Amazon associate, We'll earn a commission for every successful order through our affiliate links in the article. However, you won’t be charged anything for this.

Before diving into complex repairs, it’s important to understand that most suction issues with the Dyson DC14 can be resolved through proper maintenance and cleaning. The vacuum’s cyclonic technology relies on unobstructed airflow, so any blockage in the system can significantly reduce its effectiveness on carpet surfaces. Let’s explore the various causes and solutions to get your trusty Dyson working like new again.

Common Causes of Poor Carpet Suction

When your Dyson DC14 isn’t picking up properly on carpet, several components might be causing the problem. The most frequent culprits include:

- Overfilled dust container

- Clogged filters

- Blocked hoses or airways

- Worn-out brush roll

- Damaged belts

- Faulty clutch mechanism

- Obstructed cyclone assembly

- Issues with the bleed-off port

- Improper height settings for your carpet type

Each of these issues can significantly impact your vacuum’s performance, but fortunately, most can be resolved with simple DIY maintenance.

Essential Maintenance for Restoring Suction

Emptying and Cleaning the Dust Container

The most basic yet crucial maintenance task is emptying the dust container regularly:

- Press the release button to detach the container

- Hold it over a trash bin and press the release trigger

- Tap the sides gently to remove any clinging debris

- Wipe the interior with a dry cloth if necessary

For optimal performance, empty the container when debris reaches the MAX line—don’t wait until it’s completely full.

Filter Maintenance

Clogged filters are a leading cause of suction loss in Dyson vacuums:

- Locate the filter near the motor

- Remove it carefully

- Rinse thoroughly under cold running water

- Allow to dry completely for at least 24 hours

- Reinstall only when completely dry

Important: Never use detergents or washing machines to clean Dyson filters, and ensure they’re 100% dry before reinstalling to prevent motor damage. Clean filters every 3-6 months depending on usage frequency.

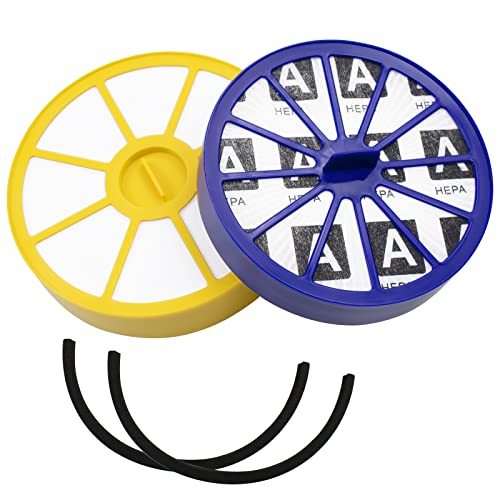

If your Dyson DC14 filter is damaged or you want to replace it after cleaning, you’ll need a new one to ensure proper filtration and suction power.

Official Dyson HEPA filter for DC14 models

Comprehensive filter set for DC14/15 with HEPA and pre-motor filters

Cost-effective replacement with enhanced filtration

Complete filter kit for DC14/15 with easy installation

Clearing Hose Blockages

Blocked hoses dramatically reduce suction power:

- Detach the hose from both ends

- Visually inspect for blockages

- Use a long, flexible tool (like a straightened wire hanger with taped ends) to gently push through any obstructions

- Pay special attention to bends and connection points

- Run water through the hose to flush out stubborn debris

To prevent future blockages, avoid vacuuming damp materials and store the hose without sharp kinks.

Brush Roll Maintenance

A tangled or worn brush roll can significantly impact carpet cleaning performance:

- Turn off and unplug the vacuum

- Flip it over to access the brush roll

- Cut away any tangled hair, string, or fibers

- Check for signs of wear or damage

- Listen for the ratchet sound when the vacuum is running—absence may indicate a broken belt

If the brush roll is heavily worn or damaged, replacement may be necessary for optimal performance.

If your brush roll is worn down or damaged, it’s time for a replacement to maintain effective carpet cleaning.

Affordable replacement with end caps and belts

High-quality replacement for deep cleaning

Includes replacement brush bar and caps

Comprehensive kit with tool and belts

Advanced Troubleshooting and Repairs

Checking and Replacing the Belt

When your DC14’s brush roll isn’t spinning properly:

- Unplug the vacuum and lay it flat

- Remove the soleplate (usually secured by screws)

- Inspect the belt for signs of wear, stretching, or breakage

- If damaged, remove the old belt and install a new one

- Ensure proper tension and alignment

- Reinstall the soleplate and test

A properly functioning belt will allow the brush roll to spin freely and create the characteristic ratcheting sound when it encounters resistance.

If the belt is broken or stretched, replacing it will restore the brush roll’s spinning action.

Official replacement belt for optimal performance

Durable elastic rubber belts with clutch compatibility

Precision-engineered clutch system components

Full system replacement for brush roll issues

Addressing Cyclone Assembly Issues

Fine dust can accumulate in the cyclone assembly, affecting airflow:

- Separate the cyclone assembly from the clear bin

- Tap it firmly on a solid surface to dislodge caked-on dust

- Rotate and tap from different angles to clear all internal channels

- Check for visible blockages in the cone openings

- Reassemble carefully, ensuring all seals are properly seated

This maintenance step is often overlooked but can make a significant difference in suction performance.

Clearing Internal Blockages

Several critical areas are prone to internal blockages:

- U-bend: Located at the base of the vacuum

- Pre-dustbin bend: The curve just before the dustbin

- Accordion hose: Located just after the brush bar

To clear these areas:

- Use a semi-flexible rubber hose or similar tool

- Avoid metal or hard plastic tools that could damage components

- Gently push through any obstructions

- Use a flashlight to verify clearance

Fixing Bleed-Off Port Issues

The bleed-off port can open prematurely if clogged with dust:

- Locate the screen on the internal part of the canister

- Clear dust buildup using the vacuum’s brush wand or a dryer lint brush

- Consider rubbing internal components with an anti-static dryer sheet to reduce future buildup

- Reassemble and test suction

Addressing Wand Suction Problems

If wand suction changes after a few seconds of operation:

- Check for blockages in the tubing

- Inspect the air diversion flap for proper function

- Examine the small hose behind the beater brush

- Clean the black mesh screen near the top of the handle section if suction changes are accompanied by a sound difference

Diagnosing Specific DC14 Issues

Hard to Push on Carpet

If your vacuum is difficult to maneuver on carpet:

- Check the height setting—it may be set too low for your carpet type

- Adjust according to carpet pile height

- If the problem started after installing new carpet, you may need to reduce suction power

- Inspect the rubber stripping around the brush area—some users report improved maneuverability after removing this

Smoking or Burning Smell

This concerning symptom typically indicates:

- A slipping rubber belt driving the brush head

- Dirt buildup in end brackets causing friction

- Possible motor issues if cleaning doesn’t resolve the problem

To address this:

- Clean the belt and brackets thoroughly

- Realign the belt if necessary

- Tighten any loose screws

- If smoking persists, seek professional motor inspection

Non-Functional Beater Bar

When the brush roll stops spinning:

- Check for worn input/output belts

- Inspect the clutch mechanism for malfunction

- Look for debris obstructing the beater bar movement

- Replace belts or rebuild the clutch assembly as needed

If the clutch is faulty, a replacement clutch assembly is needed.

Official replacement clutch for optimal performance

Authorized OEM clutch with belt replacement

Complete clutch replacement solution

Complete Clutch Replacement Procedure

For persistent brush roll issues, a clutch replacement may be necessary:

Preparation:

- Gather tools: T15 and T10 screwdrivers, flathead screwdriver, snap ring pliers

Purchase a rebuilt or third-party clutch assembly

Disassembly:

- Remove the canister and lower housing using a T15 screwdriver

- Extract the clutch shroud carefully

- Remove the old clutch, noting that components may be brittle in older models

Replacement:

- Lubricate the new clutch with isopropyl alcohol for easier assembly

- Ensure proper belt alignment during installation

- Secure the clutch firmly in place

Reassembly:

- Replace all components in reverse order

- Test the brush roller tension before final assembly

- Verify proper operation before using on carpets

Preventive Maintenance Tips

To keep your Dyson DC14 performing optimally on carpets:

- Empty the dust container before it reaches maximum capacity

- Clean filters regularly according to usage frequency

- Inspect and clear the brush roll of hair and debris after each use

- Check hoses for blockages monthly

- Inspect belts and clutch mechanisms seasonally

- Apply a small amount of oil to the brush roll ends to reduce buildup

- Store with the hose properly positioned to avoid kinks

- Use the appropriate height setting for your carpet type

Frequently Asked Questions (FAQ)

Why did my Dyson DC14 suddenly lose suction on carpets?

Sudden suction loss typically indicates a blockage somewhere in the system. Start by checking the most common areas: the dust container, filters, hoses, and brush roll. A sudden change often points to something being vacuumed up that’s caused an obstruction rather than gradual wear and tear.

How often should I clean the filters on my Dyson DC14?

The manufacturer recommends cleaning the filters every 3-6 months, but this varies based on usage. Households with pets, high foot traffic, or dusty environments may need to clean filters monthly. Always allow 24 hours of complete drying before reinstalling filters.

My DC14 makes a ratcheting noise when vacuuming. Is this normal?

Yes, the ratcheting sound is normal and indicates the clutch mechanism is working properly. This noise occurs when the brush roll encounters resistance, such as thick carpet or debris. However, if the sound is unusually loud or constant, it might indicate a problem with the clutch or belt that needs attention.

Can I use my Dyson DC14 on all carpet types?

The DC14 is designed to work on all carpet types, but performance may vary. For high-pile or plush carpets, you may need to adjust the height setting or reduce suction power. Very delicate carpets or rugs might require using the wand attachment instead of the main brush roll to prevent damage.

Why is my Dyson DC14 leaving debris behind on the carpet?

If your vacuum is leaving debris behind, check if the brush roll is spinning properly. Common causes include a broken belt, clogged brush roll, or height setting that’s too high for your carpet. Also ensure the suction channels are clear and the dust container isn’t overfilled.

Conclusion

The Dyson DC14 is a powerful and reliable vacuum when properly maintained, but like all mechanical devices, it requires regular care to perform at its best. Most carpet suction issues can be resolved through thorough cleaning and basic maintenance of key components like filters, hoses, and the brush roll.

For more persistent problems, deeper inspection of the belt, clutch mechanism, or cyclone assembly may be necessary. With the troubleshooting steps outlined in this guide, you should be able to diagnose and fix most issues that prevent your DC14 from picking up properly on carpets.

Remember that preventive maintenance is the best approach—regular cleaning and inspection of key components will extend the life of your vacuum and maintain its suction power, keeping your carpets clean for years to come.