A non-spinning brush bar on the Dyson DC07 vacuum can significantly hinder cleaning efficiency, particularly on carpets. This issue often arises from debris blockages, worn components like belts or clutches, or electrical malfunctions. This guide provides actionable steps to diagnose, troubleshoot, and resolve the problem, alongside maintenance tips to prevent future occurrences. Readers will gain insights into identifying root causes, performing DIY repairs, and understanding when professional intervention is necessary.

Affiliate disclosure: As an Amazon associate, We'll earn a commission for every successful order through our affiliate links in the article. However, you won’t be charged anything for this.

Identifying the Root Causes

Key Symptoms

A malfunctioning brush bar exhibits several telltale signs:

– The brush roll remains stationary even when the vacuum is powered on.

– Unusual noises, such as clicking or grinding, emanate from the base unit.

– Reduced suction power or intermittent spinning tied to the handle’s angle.

Common Culprits

Three primary categories of issues contribute to a stalled brush bar:

Blockages

– Hair and Debris: Accumulated hair, strings, or small objects jam the brush roll.

– Foreign Objects: Coins, paper clips, or toys lodged in the housing restrict movement.

Worn Components

– Belt: A stretched or broken belt fails to transfer motion to the brush roll.

– Clutch: A damaged clutch mechanism prevents proper engagement.

– Gears and Bearings: Wear and tear on these parts disrupts mechanical function.

Electrical Faults

– Wiring: Loose or damaged connections cut power to the brush head.

– Motor: A defective motor fails to drive the brush roll.

Step-by-Step Troubleshooting and Fixes

Safety First

- Unplug the vacuum to eliminate electrical hazards.

- Work in a well-lit, organized space to track small parts.

Clearing Blockages

- Remove the Dust Container: Press the release button and lift it out.

- Access the Brush Roll: Unscrew the base cover and inspect for tangles.

- Extract Debris: Use scissors or a cleaning tool to cut and remove hair or obstructions.

Inspecting and Replacing the Belt

- Remove the Bottom Plate: Use a T15 Torx screwdriver to detach the plate.

- Check the Belt: Look for cracks, stretching, or breaks.

- Replace if Needed: Install a new belt from a Dyson authorized retailer, ensuring it’s snug and properly seated.

Clutch Diagnosis and Replacement

- Access the Clutch Mechanism: Remove protective covers to expose the clutch.

- Test Functionality: Manually move the clutch; it should engage/disengage smoothly.

- Replace Faulty Clutch: Disconnect the old unit and install a new clutch assembly, securing it firmly.

Motor and Electrical Checks

- Motor Inspection: Look for overheating or physical damage. If compromised, seek professional repair.

- Wiring Audit: Secure loose connections and clean contacts with rubbing alcohol for optimal conductivity.

Cleaning or Replacing the Brush Roll

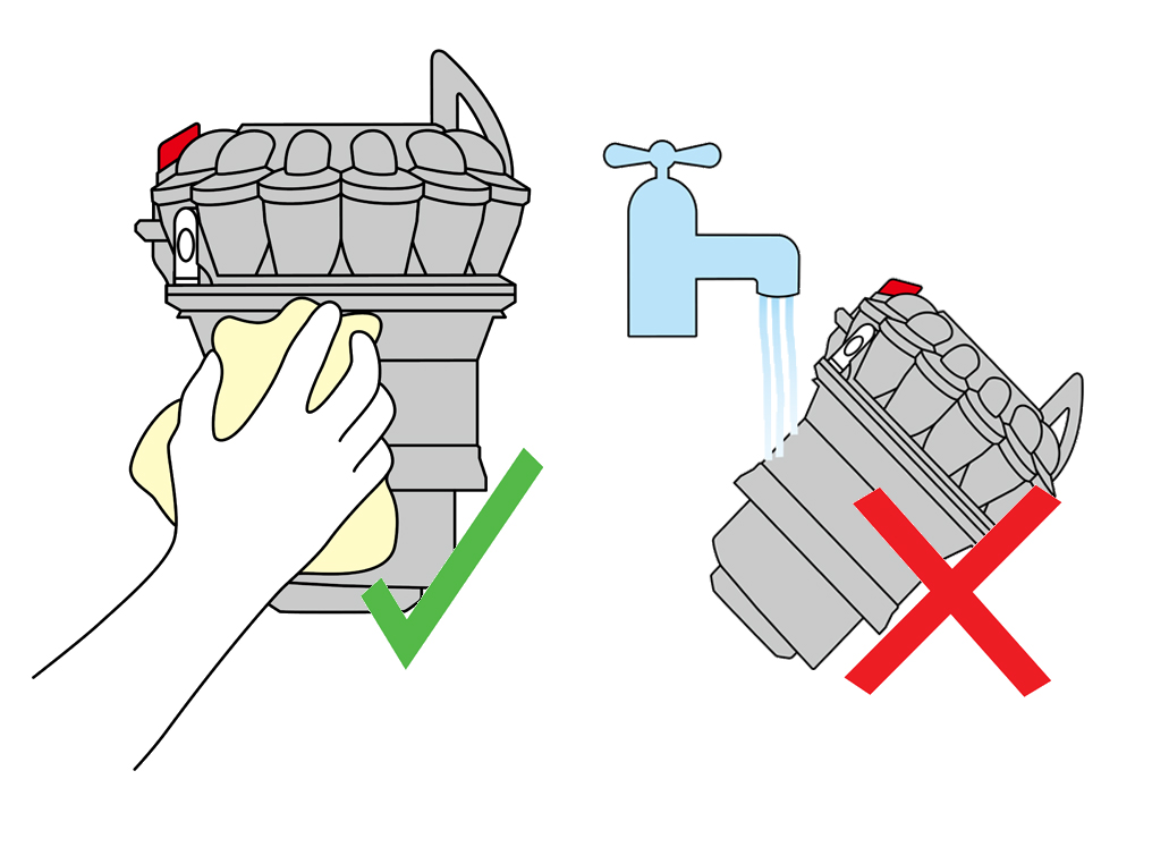

- Remove and Clean: Slide the brush roll out, trim tangled hair, and wipe debris.

- Replace if Damaged: Purchase a new brush roll if bristles are broken or excessively worn.

Preventive Maintenance Strategies

– Regular Cleaning: Remove the brush roll after each use to clear hair and debris.

– Check for Wear: Inspect the belt and clutch monthly for signs of deterioration.

– Avoid Overloading: Empty the dust bin frequently and avoid vacuuming large objects.

– Optimize Airflow: Clean filters and hoses regularly to prevent clogs.

Advanced Troubleshooting

If the brush still won’t spin after basic fixes:

– Motor Issues: Test the motor for power output or visible damage.

– Internal Blockages: Disassemble the head further to inspect hidden obstructions.

– Electrical Obstruction Cleaning: Clean connection points with rubbing alcohol to restore conductivity.

User Experiences and Tips

Immediate Fixes

- Reset the Brush Button: Unplug the vacuum, wait a few minutes, then press the roller button for 5 seconds after restarting.

- Manual Clutch Adjustment: Flip the vacuum and adjust the clutch mechanism to restore engagement.

Preventive Maintenance

- Clean the Small Brush: Use a T10 Torx tool to remove hair wrapped around the shaft.

- Regular Inspections: Check components after each use to catch early signs of wear.

DIY Repairs: Pros and Cons

Pros:

– Cost-effective compared to professional services.

– Immediate resolution without waiting for repairs.

Cons:

– Risk of damaging components if inexperienced.

– Potential warranty void if manufacturer guidelines are bypassed.

Model-Specific Considerations

– Syntec Models: Rely on turbine mechanisms rather than electrical connections.

– V6 (DC59): Focus on electrical contact cleaning.

– DC14/DC07/DC33: Clutch replacement is critical, with 80% of repairs addressing this part.

Frequently Asked Questions (FAQ)

What are the signs of a blocked brush roll?

Reduced suction, unusual noises, and intermittent spinning are common indicators.

How do I know if the belt is damaged?

Inspect for cracks, stretching, or slippage during operation.

Can I replace the clutch myself?

Yes, but ensure you follow precise steps and secure a compatible replacement part.

Conclusion

Resolving a Dyson DC07 brush bar issue involves systematic troubleshooting, from clearing blockages to replacing worn components. Regular maintenance and prompt repairs can extend the vacuum’s lifespan and maintain optimal performance.

If DIY fixes prove insufficient, consult Dyson’s customer support or a certified technician to avoid further damage. By prioritizing preventive care, users can minimize disruptions and keep their cleaning routine efficient.