Dyson DC25 owners often face a frustrating problem: the brush bar stops spinning mid-clean. This issue disrupts the vacuum’s ability to lift dirt effectively, leaving carpets and floors only partially cleaned. Symptoms vary—from the brush bar stalling after a few rotations to erratic spinning depending on the handle angle. While the problem may seem daunting, many fixes are straightforward for DIY enthusiasts.

Affiliate disclosure: As an Amazon associate, We'll earn a commission for every successful order through our affiliate links in the article. However, you won’t be charged anything for this.

This article explores the root causes of the Dyson DC25 brush bar malfunction, including blockages, electrical faults, and wear-and-tear. Step-by-step troubleshooting guidance, maintenance tips, and insights into cost-effective repairs are provided to help users restore their vacuum’s performance. Whether you’re dealing with intermittent spinning or a complete stall, this guide covers solutions tailored to your needs.

Common Causes Behind Brush Bar Malfunctions

Several factors can prevent the Dyson DC25 brush bar from spinning:

- Blockages: Hair, threads, or debris around the brush roll create friction, halting its rotation.

- Wear and Tear: Cracked bristles, damaged bearings, or worn components reduce efficiency.

- Electrical Issues: Faulty wiring, overheated motors, or damaged power cords disrupt power delivery.

Identifying the root cause is critical. For instance, a tripped reset switch due to overheating might mimic motor failure. Similarly, a frayed wire at the hinge joint could cause intermittent operation.

Reset Switch Troubleshooting

A tripped reset switch often causes sudden brush bar failure. Located near the motor housing, this safety feature cuts power during overheating or overloading. To reset:

- Turn off and unplug the vacuum.

- Remove the top cover to access the motor.

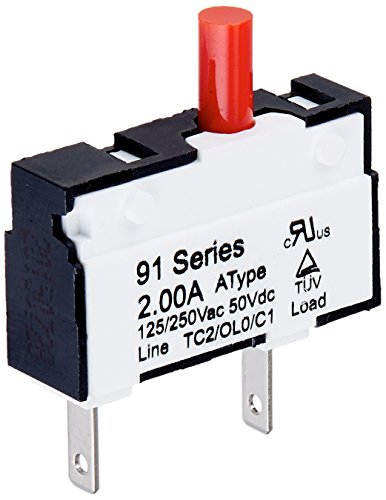

- Press the red or black reset button near the brush roll motor.

If the button doesn’t pop back out, replace the switch. Reassemble and test the brush bar. Regularly inspecting this component prevents recurring issues.

If the reset switch is faulty or damaged, replacing it will restore power to the brush bar motor.

Official replacement ensuring compatibility and quality

High-quality replacement with overload protection

OEM-approved replacement for electrical safety

Dual switches with overload safety features

Fixing Intermittent Spinning

A common culprit is loose or damaged wiring in the side assembly hinge. To address:

- Unplug the vacuum and remove the bottom cover.

- Locate the white power cable at the hinge joint.

- Repair broken wires via soldering or replace the cable entirely.

This issue often arises from repeated bending, which strains connections. Securing wires during reassembly minimizes future stress.

Lubrication for Smooth Operation

Friction from dry components can impede rotation. Apply a small amount of WD-40 to:

- The brush roller’s ends

- The removable cap that houses the roller

Avoid over-lubricating, as excess oil attracts dust. Regular lubrication extends the brush bar’s lifespan and ensures consistent performance.

Step-by-Step: Replacing the Brush Roll Motor

If electrical checks confirm motor failure, replacement is necessary. Gather:

- Flathead and Phillips screwdrivers

- Replacement motor

- Soft workspace padding

Procedure:

- Detach the Dust Container: Remove rear casing screws and set aside.

- Disconnect the Old Motor: Unplug electrical connectors and unscrew the motor.

- Install the New Motor: Align and secure with screws, then reconnect wires.

- Reassemble: Reattach the rear casing and dust container.

Test the vacuum for smooth brush bar rotation and unusual noises. Third-party motors offer a budget-friendly alternative to OEM parts.

Maintenance Best Practices

Preventive care minimizes breakdowns:

– Clean the brush roll after each use to remove hair and debris.

– Inspect filters monthly and replace if damaged.

– Store upright in a dry, shaded area to avoid component stress.

Regular checks of wiring and bearings also extend the vacuum’s lifespan.

Pros and Cons of DIY Repairs

Pros:

– Cost savings compared to professional services.

– Enhanced performance post-repair.

– Personal satisfaction from self-repair.

Cons:

– Complex steps may overwhelm beginners.

– Risk of damaging components during installation.

– Time-intensive for first-time repairs.

Prioritize sourcing generic or third-party parts to cut costs without sacrificing quality.

Frequently Asked Questions (FAQ)

Why does my DC25 brush bar spin briefly then stop?

A tripped reset switch or partial motor failure is likely. Reset the switch first; if the issue persists, test the motor.

Can I replace Dyson DC25 switches with generic ones?

Yes. Generic switches (available on platforms like eBay) work effectively and cost significantly less.

Is it worth repairing an older DC25 model?

Yes, repairing individual components (e.g., wiring, switches) is far cheaper than buying a new unit.

How do I check for wiring issues?

Inspect the red wire near the switch and motor connections for cuts. Use a multimeter to test continuity.

Conclusion

The Dyson DC25 brush bar issue, while common, is often solvable with basic tools and patience. From resetting the switch to replacing the motor, these fixes empower users to extend their vacuum’s life. Prioritize regular maintenance and cost-effective DIY repairs—like using generic switches or third-party motors—to keep your DC25 running smoothly. When faced with complex electrical faults, consult a professional to avoid further damage. With these strategies, your Dyson will regain its cleaning prowess in no time.