A vacuum cleaner’s brush bar is critical for effective cleaning, but when the Dyson DC24 roller stops spinning, it can hinder performance. This issue often stems from mechanical or electrical faults, ranging from simple obstructions to complex motor problems. Understanding the root causes and solutions can save time, money, and frustration.

Affiliate disclosure: As an Amazon associate, We'll earn a commission for every successful order through our affiliate links in the article. However, you won’t be charged anything for this.

This article explores why the Dyson DC24 brush bar might stop rotating, offering step-by-step troubleshooting, repair techniques, and maintenance tips. Whether you’re dealing with tangled hair, a worn belt, or a faulty switch, this guide provides actionable insights to restore your vacuum’s functionality.

Common Causes of Brush Bar Failure

The Dyson DC24 brush bar relies on a combination of mechanical and electrical components to spin effectively. Key culprits behind its failure include:

- Obstructions: Hair, strings, or debris around the roller can immobilize it.

- Worn or Broken Belt: The belt connecting the motor to the brush bar may snap or lose tension.

- Motor Malfunctions: Electrical issues or motor damage can disrupt power delivery.

- Gear Damage: Misaligned or worn gears in the transmission system may prevent rotation.

- Stuck Grey Brush Button: A jammed switch can interrupt the electrical signal.

- Frayed Wires: Damaged wiring in the ball pivot area causes intermittent operation.

- Faulty Lever Switch: A defective switch inside the vacuum’s “ball” assembly can cut power to the brush.

Identifying the exact cause is the first step toward a fix.

Step-by-Step Troubleshooting Guide

Clearing Obstructions

- Turn off and unplug the vacuum.

- Remove the bottom plate using a screwdriver to access the brush bar.

- Inspect for tangled debris like hair or strings.

- Use scissors or a seam ripper to carefully cut and remove obstructions.

Replacing the Belt

- Locate the belt connecting the motor to the brush bar.

- Check for cracks, stretching, or breakage.

- Install a replacement belt (Dyson or third-party) by looping it around the motor spindle and brush bar.

Testing the Motor and Gears

- Use a multimeter to verify the motor’s electrical connections.

- Inspect gears for wear or misalignment.

- Lubricate or replace damaged gears with manufacturer-approved parts.

Addressing Electrical Faults

For issues like frayed wires or faulty switches:

– Repair or replace damaged wiring in the ball pivot area.

– Test the lever switch for continuity and clean contacts with a file if necessary.

Specific Brush Bar Problems and Solutions

Stuck Grey Brush Button

- Gently pry the grey button upward using a flat tool like a butter knife.

- Test the brush bar to confirm rotation resumes. If the button is physically damaged, replace it.

Snapped Red Reset Button

- Order a replacement from Dyson or authorized retailers.

- Install the new button following manufacturer instructions.

- Press the reset button while the vacuum is powered off to restore function.

Frayed Wires in the Ball Pivot

- Access the ball pivot area by removing the outer casing.

- Reconnect or replace damaged wires, ensuring secure contact.

- Test the brush bar at different handle angles to confirm stability.

Faulty Lever Switch

- Remove the “ball” wheels to access the lever switch.

- Clean contacts with a small file and apply dialectic grease.

- Replace the switch if it fails continuity tests.

Expert Repair Techniques

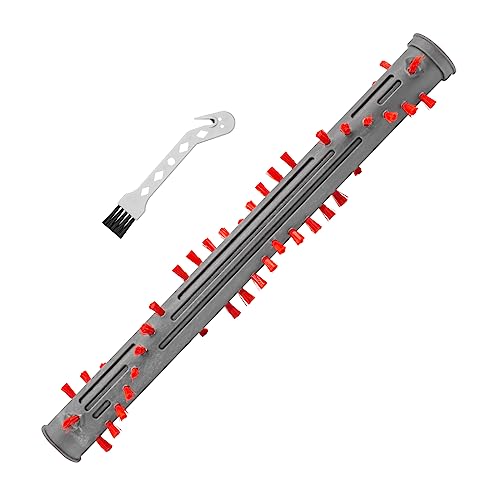

Replacing the Brush Bar

- Unscrew and remove the old brush bar.

- Insert a new bar and secure it with screws.

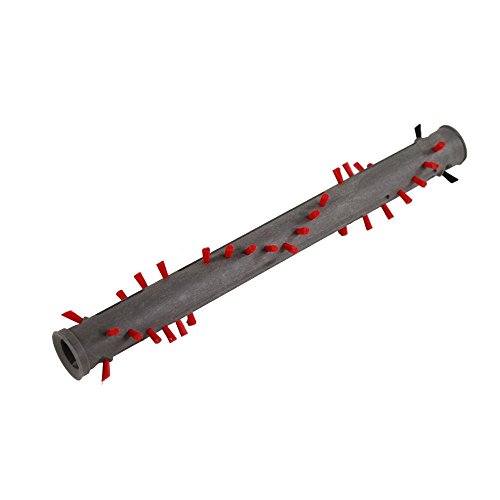

Official Dyson replacement for DC24 with durable nylon bristles

Affordable third-party option with compatible nylon bristles for DC24

Budget-friendly compatible brush roller with nylon bristles

Motor Replacement

- Disconnect electrical wiring and unscrew the motor.

- Install the new motor and reconnect all cables.

Gear Assembly Fixes

- Disassemble the gear housing and inspect for damage.

- Replace worn gears (approximate cost: $7.50 USD for a cog assembly).

- Modify mounting holes if needed to fit replacement parts.

Maintenance Tips for Longevity

Regular Cleaning

- After each use, clear debris from the brush bar.

- Check the belt monthly for wear and replace as needed.

Proper Storage

- Store upright to avoid pressure on the brush bar.

- Avoid extreme temperatures to prevent plastic warping or belt degradation.

Pros and Cons of DIY Repairs

Pros:

– Cost-effective compared to professional services.

– Quick fixes for common issues like obstructions or belt replacement.

– Opportunity to learn about vacuum mechanics.

Cons:

– Risk of damaging sensitive components.

– Time-consuming for complex repairs.

– Potential warranty void if not performed by an authorized technician.

Frequently Asked Questions (FAQ)

Why does my Dyson DC24 brush bar stop spinning randomly?

Intermittent operation often stems from frayed wires in the ball pivot area or a faulty lever switch. Check these components for damage or loose connections.

How do I know if the belt is broken?

A broken belt typically results in a silent brush bar despite the motor running. Inspect the belt for cracks or disconnection from the motor spindle.

Can I use third-party replacement parts?

Yes, reputable third-party belts and brush bars are compatible, but ensure they meet Dyson’s specifications for durability.

What voltage should the motor receive?

The input voltage to the PCB is ~230V AC, while the motor output should measure ~330V DC.

How do I clean the brush bar bearings?

- Remove non-standard star-shaped screws.

- Clean bearings with a brush and reapply grease to ensure smooth rotation.

Conclusion

A non-spinning Dyson DC24 brush bar can often be resolved with basic troubleshooting, from clearing debris to replacing worn parts. For complex electrical or mechanical failures, consider professional assistance to avoid further damage. Regular maintenance, such as cleaning and belt checks, prolongs the vacuum’s lifespan. By addressing issues promptly, you can maintain optimal cleaning performance and extend the durability of your Dyson DC24.